Engineering the Future of Farming

Over the next 25 years, the world’s population, currently hovering around 7.8 billion, is expected to grow by nearly 25% to 9.7 billion people. This means that existing global problems such as food, energy and water security are only going to become more acute.

“Just consider water alone. Agriculture accounts for 70% of global water usage,” says Cherie Kagan, Stephen J. Angello Professor in Electrical and Systems Engineering (ESE) and Director of the Internet of Things for Precision Agriculture (IoT4Ag) Center at Penn. “When we were looking at opportunities to unite research excellence across disciplines in Penn Engineering and to tackle a societal grand challenge, agriculture and its importance to global food, energy and water security came to the forefront.”

On its face, a university located on nearly 300 acres within a major East Coast city isn’t where you’d expect to find a center focused on agriculture. But when you dig beneath the surface, Penn Engineering’s expertise in areas like sensors, robotics, materials, manufacturing and data science, together with a proven track record of collaboration, make it the ideal institution to lead such an effort.

IoT4Ag, established in September 2020, just closed out its third year as Penn’s first NSF Engineering Research Center (ERC). The Center’s members from Penn Engineering and its three partner institutions across the U.S. have leveraged their collaborative expertise to produce new technologies aimed at creating the farm of the future: one that would collect, communicate and harness real-time data to efficiently deploy resources and improve crop yields with the least possible impact on the environment.

Cherie Kagan

Stephen J. Angello Professor, Electrical and Systems Engineering and Materials Science and Engineering

Director, IoT4Ag

Nexus of Innovation

“IoT4Ag is the quintessential example of the School’s Energy and Sustainability Signature Initiative,” says Vijay Kumar, Nemirovsky Family Dean of Penn Engineering and member of IoT4Ag. “Not only are there significant advances in sensor, battery and biodegradable technologies coming out of the Center, but these advances are coming together to produce pathbreaking, data-driven solutions that will change agriculture and how it impacts the planet for decades and even centuries to come.”

As an ERC, IoT4Ag is led by Penn and spans across three collaborating campuses: the University of Florida, Purdue University and the University of California, Merced. The Center’s goals are not only focused on R&D for new technologies but also include inspiring and training a diverse workforce and building an innovation ecosystem that facilitates the transfer of technology from the lab to the market.

“We want to make sure that the work in the Center is greater than the sum of its parts so that we can achieve something big,” says Kevin Turner, Professor and Chair of Mechanical Engineering and Applied Mechanics and the Convergent Research Director for IoT4Ag. “An Engineering Research Center is the premier center program within the NSF Engineering Directorate, and Penn being the lead institution for IoT4Ag is a reflection of the significant investment in research that Penn Engineering has made over the past two decades.”

Research in the Center is organized into three thrusts, with the first focused on sensors and robotics technologies, the second being communication and power solutions and the third on developing data-driven models and decision frameworks. “For the Center to realize its full potential, you need all of these things to come together,” continues Turner, who also serves as the Penn Site Director for IoT4Ag. “As individual technologies are developed in the thrusts, they are integrated into systems that are deployed in test fields at our collaborating institutions to demonstrate and assess the efficacy of the technology.”

Not Sustainable

In addition to water use issues, the agricultural industry faces other concerns: the land available for farming is shrinking rather than growing, energy costs are one of the largest expenses on a farm, and overuse and leaching of fertilizers and other chemicals is expensive and not environmentally sound.

“We know that watering, and applying nitrogen treatments at the right times and in the right amounts, will improve crop yield,” says Troy Olsson, Associate Professor in ESE and Thrust 1 Co-Lead for IoT4Ag. “Chemicals, which have gotten more expensive with riskier supply chains, are overapplied because farmers can’t afford not to do so. The result is that the yields are high, but so are the resource expenditures.”

One method to determine conditions on a farm uses sensors. However, sensors today undersample the large scale of farms because they are deployed at the acre-scale or greater, cost hundreds of dollars, are big and require power sources and radio infrastructure to communicate.

“Many of the mechanisms available to view the status of crops on a farm are only visible once damage has occurred; there is no early warning system,” says Olsson. “Waiting for symptoms to manifest in order to determine there is a problem in agriculture, just as in health care, can mean it’s far too late.”

“Today, there is very limited data available to a farmer to control things like irrigation,” he continues. “The situation is even worse when we get into stressors like soil nutrient levels because current soil testing involves shipping samples to a lab. Data comes back weeks later and it’s only from the spots that were sampled, not the entire farm.”

“There have been tremendous advances in agriculture over the past century,” adds Turner. “The amount of food that we produce per acre of land has grown substantially over the past 100 years. But as you look toward the future, the challenge is feeding a growing population on less land while using fewer resources. New technologies are needed to overcome this challenge.”

Nationwide Collaboration

While Penn Engineering possesses many strengths in terms of developing the novel technologies needed to create the farm of the future, collaboration is key for the Center to succeed.

Each collaborating institution possesses researchers working in all three thrusts, but expertise in agronomy is found at the test beds located at Purdue University, the University of Florida and the University of California, Merced.

“The team is not solely engineers, there are agronomists and agricultural engineers, disciplines we don’t really have on Penn’s campus,” says Kagan. “With Florida, you get the southern part of the U.S., in Merced, you get the West, and in Purdue you get the Midwest, with all three representing different climates and different cropping systems to put the Center’s technology into practice.”

Biodegradable Sensors

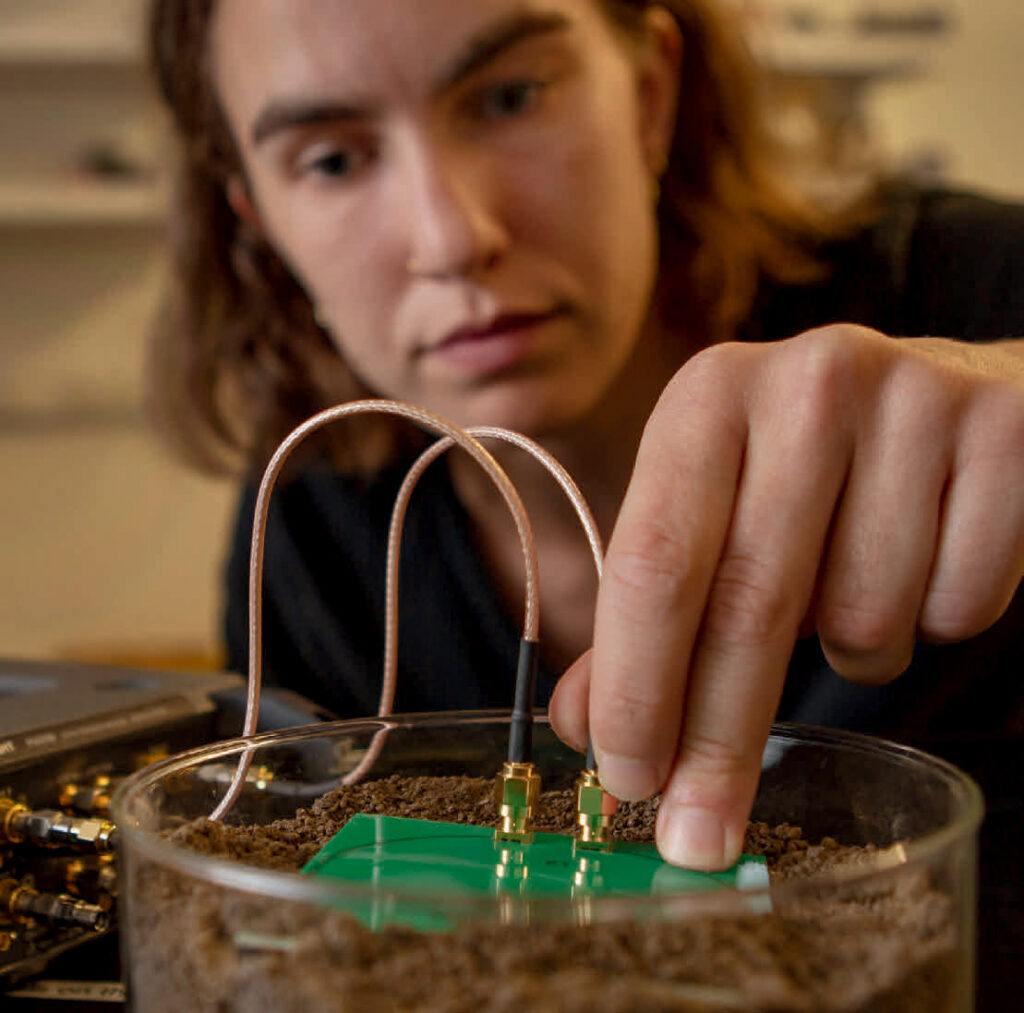

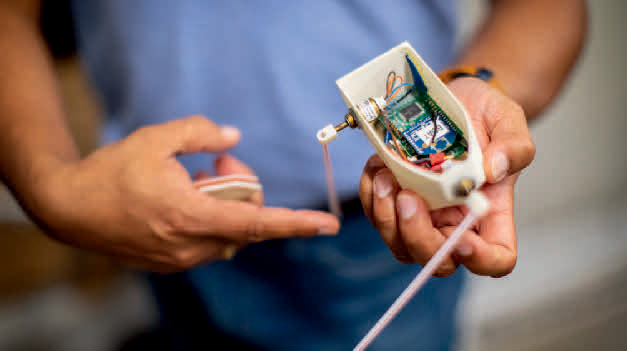

IoT4Ag has leveraged low-cost, high-volume technologies to develop fully biodegradable, passive soil moisture sensors measuring approximately three square inches that can be deployed beneath the ground. The sensors consist of a paper substrate infiltrated with cellulose nanofibrils (CNFs) on which inks made from non-harmful metal nanoparticles are screen printed to produce both the sensing element needed to measure soil moisture and the communication (antenna) needed to communicate with a reader.

Working within the range of a tractor driving over the sensor, the reader interrogates and wirelessly collects the sensor’s data. Following deployment in the soil, the sensors remain dormant until they are interrogated, which means they don’t require a local power source. They instead reflect energy from the reader, much like RFID technology, in order to function. The sensor is currently being tested in soils for row crop farming, and IoT4Ag researchers are working to tailor the same technology for sensing nitrogen and other quantities applicable to agriculture.

Changing What’s Possible

To engineer the farm of the future, IoT4Ag researchers envision fields with precision sensors that are low-cost, deployed widely and that work with farming infrastructure and local communications systems that would provide better data to advise prescriptive treatments, perhaps even at the plant level, for problems that could be mitigated immediately.

“In large agricultural fields, there is limited infrastructure,” says Turner. “Power is limited, and wireless communication technology is even more scarce.” To work within the constraints of farms and their rural settings, IoT4Ag researchers focused their efforts on developing novel sensor technologies, first producing a low-cost, fully biodegradable soil moisture sensor [see above].

“Our goal is to widely deploy sensors that, instead of costing hundreds of dollars, cost a penny, are passive in their power use or have biodegradable batteries, and can biodegrade into the soil instead of needing to be collected,” says Olsson, who together with Turner developed IoT4Ag’s biodegradable moisture sensors.

To augment the capabilities of the sensors and make them multi-use, technology will be needed in the form of processing chips and batteries. Labs across the Center are addressing this need by developing biodegradable batteries and small silicon chips that would allow sensors the ability to measure quantities of chemicals such as phosphates that aren’t easily collected using passive monitoring techniques.

In addition, Kagan and Turner are collaborating to develop colorimetric sensors that can stick to the leaves of plants and change color based on the measured target. If these sensors are passed over by a camera, they can be read.

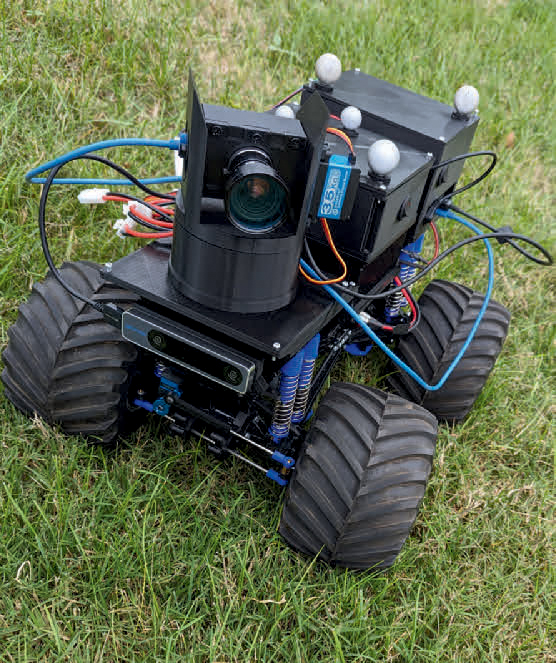

The sensors being developed can be interrogated by adding cameras and radio-frequency reader technology to existing farm equipment, such as tractors, but another Penn Engineering strength, robotics, is key to data harvesting as well. Using drones, like those found in the lab of Kumar, expands the methods for reading the sensors and therefore monitoring field conditions, but drones come with their own limitations, namely how long they can stay in the air.

The lab of Sue Ann Bidstrup Allen, Professor in Chemical and Biomolecular Engineering and Workforce Development Co-Director for IoT4Ag, is working to create alternate battery technologies for drones to increase flight times. “Drones currently use lithium-ion batteries, which limit flights to 30 minutes or so, which is problematic for agricultural uses,” says Bidstrup Allen. “We are looking at alternative chemistries, such as those currently being used in hearing aids, that could be used as energy sources.”

To get the data from the field into the cloud and turn it into a useful tool, IoT4Ag members are collaborating to create an interface that will take the data measured in different areas, plus weather and other environmental data, and stitch it together, modeling it into a tool that could suggest how participating farmers could manage and deploy resources on their own specific farms.

Small, networked ground robots use cameras to monitor optical sensors such as those pictured below in the undercanopy of crops.

IoT4Ag researchers have developed novel colorimetric sensors that can stick to the leaves of plants and change color based on the measured target, such as moisture and temperature levels, enabling precision monitoring of crop health.

Future Farmers

In addition to the interdisciplinary research at Penn, Purdue, Merced and Florida, IoT4Ag has partners in education, government, industry and the farming community at large. This not only ensures the Center will produce viable technologies, but that those technologies will be more readily adopted and that there will be individuals excited to pursue careers at the intersection of technology and agriculture. IoT4Ag participates in symposiums, conferences and other events for agriculture practitioners and offers courses to students across the four partner institutions.

The mindset of any industry can be one of “if it works, don’t break it,” which can be a barrier to adoption of new methods. However, agriculture-rich schools like Purdue and University of Florida boast robust community extension programs, which are designed to bring new opportunities and technologies to farmers and individuals working in agriculture. They understand the local community and have existing, longstanding relationships.

“Trust is paramount,” says Kagan. “Leveraging extension relationships where trust already exists allows us to work with early adopters who can act as ambassadors.”

“Those partners are also an important way to receive feedback from the end-user community throughout the entire design process,” adds Turner. “If we make something, but it doesn’t work with current practices, nobody will adopt it.”

The average age of the farmer is increasing, so exposing agronomy-centric ideas to students interested in STEM is critical, and IoT4Ag does just that at multiple levels in the educational journey. “Young people can think of agriculture as an old-fashioned field, and they don’t realize how high-tech it is getting,” says Bidstrup Allen. “At the same time, they want to see that they can contribute to the betterment of mankind, and it’s easy to see that linkage through agriculture. If you want to be an engineer, knowing that agriculture is an option for an exciting career is key to the future of the industry.”

To that end, Bidstrup Allen and her colleagues in Workforce Development oversee initiatives designed to spark interest in STEM and agriculture, including contributing lessons to a summer camp for underserved Philadelphia middle school students located in Penn’s Morris Arboretum and run by ACLAMO, a nonprofit community service organization. IoT4Ag also welcomes local educators to Penn’s campus to engage in its Research Experience for Teachers (RET) program, where educators can work in faculty labs on projects and advise the Center on its STEM activities to make them accessible to multiple age groups.

“A lot of students care about the environment, and they want to make a difference,” says Kagan. “We are showing them that agriculture is a place that bridges both of those desires. The idea of introducing technology and innovation to agriculture may also be a way to bring the next generation back to the idea of farming.”

Looking Ahead

As the Center enters its fourth year, researchers are excited by the emerging sensor technologies they’ve developed and are eager to see how they function once deployed, but just like farmers, they are beholden to the rhythms of nature.

“One of the challenges with agriculture that you don’t have in normal lab settings is that there is a growing season each year, which differs in length and the crops that are farmed across the U.S.” says Kagan. “I can go anytime to my lab and get data. On a farm, you have to collect data within the growing season. Now that we are in year three, we have enough data where we can see a full picture coming together and we can start to build models to address key problems.”

“We aren’t there yet, but we’ve made significant progress,” notes Olsson. “We’ve taken the first step and shown that a biodegradable, low-cost, widely deployable soil moisture sensor is indeed possible, and getting it to longer ranges, reducing its size, and tailoring it to measure different targets, particularly nitrogen at multiple depths, is the next step we need to tackle.”

IoT4Ag has laid its foundation and now it’s a matter of execution, refining the technologies and turning toward the full system that the team is hoping to eventually put together. “I’m proud of the culture and the impact of the Center,” says Kagan. “Members are learning a lot from one another and the communities they are connected with.”

“In 50 years,” predicts Turner, “you’ll drive by a field that won’t look much different than it does today, but it will have much better sense and response systems that lead to lower resource use and higher yield due to technologies that will be developed by this Center and others like it in the coming years.”

“The impact of IoT4Ag will be developed over many years,” adds Bidstrup Allen. “It takes time to make the changes we need to feed a hungry world.”

Energy + Sustainability in Penn Engineering

Energy and Sustainability is one of Penn Engineering’s three Signature Initiatives. Efforts in the School span across centers like IoT4Ag, individual faculty research projects, academic programs, student projects and even the School’s physical plant. The array below shows just a few examples of the ways in which Penn Engineers are working toward a more sustainable, energy-secure future.

Pulling Water from Air

To collect atmospheric water without an external energy source, Shu Yang, Joseph Bordogna Professor and Chair of MSE, and Paulo Arratia, Professor in MEAM, have advanced sustainable building envelope tech by using kirigami, a material cutting and folding technique.

Current-Propelled Robots

Research from the GRASP Lab’s Scalable Autonomous Robots Lab, led by M. Ani Hsieh, Associate Professor in MEAM, is using marine robots to map ocean currents, which would enable more energy-efficient exploration and monitoring of our oceans.

Turning Carbon Emissions into Rocks

The Clean Energy Conversions Lab, led by Jennifer Wilcox, Presidential Distinguished Professor of Chemical Engineering and Energy Policy in CBE, and Peter Psarras, Research Assistant Professor in CBE, is repurposing industrial waste, converting carbon dioxide into stable rocks.

Embodied Carbon Tech

Penn Engineering’s Amy Gutmann Hall, set to achieve LEED Gold status, will be Philadelphia’s first large mass-timber building, a construction technology that uses wood to achieve a design with a 70% lower embodied carbon footprint than a comparable steel and concrete building.

VIPER’s Next-Gen Scientists

The Vagelos Integrated Program in Energy Research (VIPER) is a dual-degree program that prepares undergraduates to become energy science leaders and innovators through cutting-edge research experiences in alternative and efficient methods of production, conversion and use of energy.

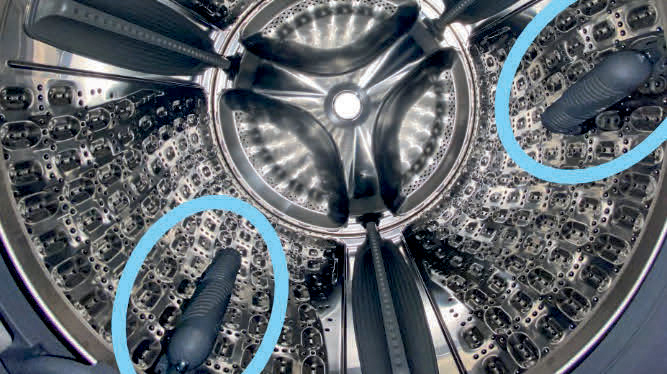

Trapping Microplastics

2022 MSE alums Sarah Beth Gleeson, Shoshana Weintraub and Julia Yan cofounded the startup Baleena while undergraduates, creating an in-drum laundry device to capture microfibers, the small strands of plastic thread that shed from synthetic clothing, to reduce microplastic pollution in water.

The Future of Energy Research at Penn

The new Vagelos Laboratory for Energy Science and Technology (VLEST), a Penn Engineering and Penn Arts & Sciences collaboration, is on track for LEED Platinum status, a Penn first, due to its high-performance façade and energy recovery systems that lower energy consumption by 63%.

Learn more about Penn Engineering’s Energy and Sustainability Signature Initiative.

Story by Olivia McMahon / Cherie Kagan photo by Leslie Barbaro / Lab photo by Kevin Monko